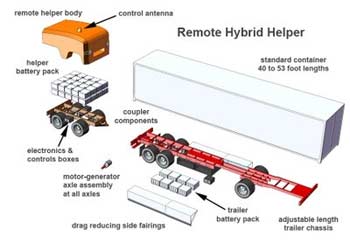

The Remote Hybrid Helper is an innovative approach for making an add-on system so semi-trailer trucks function as hybrids. A special trailer chassis and remote hybrid helper provide multiple levels of regenerative braking and energy storage. The stored energy is then used to boost fully loaded tractor trailer combos up hills, or to start-up in problem smog zones, such as port facilities, with reduced emissions. The system in one of several versions should provide increased fuel economy and reduced criteria pollutants by converting the energy lost in braking to energy for propulsion.

Standard trailers used to haul intermodal containers are steel girder chassis with sets of tandem wheels. After offloading from ships or trains, containers are mated to the chassis, and a diesel powered semi-tractor unit couples on the chassis. In the HSTA concept, electric motor-generators are integrated into the trailer chassis’ tandem wheel axles. Similar to a hybrid car (Toyota Prius for example), the motor generators produce electricity via regenerative braking instead of normal friction brakes. A bank of batteries can be mounted under the trailer chassis (lots of room!) to store this energy.

When the truck/trailer combo needs to accelerate or go uphill, electric power flows from the batteries to the motors to provide some or all the power needed to propel the truck. The tractor’s diesel engine can be left at idle or even shut down until the batteries’ stored energy is drained. No modifications to the tractor other than perhaps some added control boxes are needed. So any of the hundreds of thousands of existing tractor trucks can become a hybrid by coupling up to one of these new modular chassis.

An alternative implementation of this idea is to duplicate or move the motors and batteries to a remote control guided helper vehicle. The remote hybrid helper vehicle, or”RHH”, couples to the rear of the trailer going either up or down hills, or in port facilities. On downhills the RHH’s motor/generators charge up it’s battery bank using regenerative braking, to be used to boost the trailer uphill, or from a stop. The unique twist is that the helper can decouple from the downhill bound vehicle after providing braking, and couple up to an uphill bound vehicle to push it up the hill.

The unique benefit is that the RHH is an exchange medium for collecting the potential energy of the downhill bound tractor-trailer combination, and handing it off to another uphill bound vehicle. And the vehicle itself doesn’t have to carry the cost and weight of the battery-motor system on long, flat runs where it might not provide any benefit. Further, in a dense transport environment like a port or city, the RHH vehicles could be charged up from the utility grid, and provide smog-free propulsion to get the semi-truck out on the open road. Of course, we'd want to have a high efficiency, low emission utility power plant powering the grid.