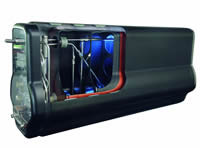

BMW Group Forschung und Technik, the company's research and technology arm, has been working with other car manufacturers to achieve an important step forward in hydrogen storage. Teaming up with partners, including some from the European aerospace industry, the engineers have developed a novel type of tank made of composite material for storing liquid hydrogen.

Thanks to its innovative concept, the weight of the entire tank system can be reduced to a third compared with conventional cylindrical steel tanks. Its adaptable form lends it a high degree of flexibility, allowing for significant energy savings. The subsidiary systems, moreover, are integrated inside the tank's casing, which means the tank takes up less room in the car and maintenance is also made much easier. The inner tank is designed on a modular basis, simplifying the production process in comparison with existing hydrogen tanks.

Prof. Dr.-Ing. Raymond Freymann, Director of BMW Group Forschung und Technik: "The demonstration model of the new free-form tank being presented marks an important step forward into the hydrogen future. Filled with ten kilograms of hydrogen, it could allow a range well in excess of 310 miles in a future vehicle."

BMW Group Forschung und Technik is presenting the prototype of this innovative liquid hydrogen storage tank at the final event of the "StorHy" EU project in Poissy near Paris on 3 and 4 June 2008. In the past four and a half years BMW Group Forschung und Technik, along with 34 partners from the European aerospace industry, the automotive and supply industry, and leading universities and research institutes, has been investigating ways of advancing current hydrogen storage technologies (high-pressure, liquid and solid storage). The cost of the project was 18.7 million euros, with EU funding to the sum of 10.7 million euros.