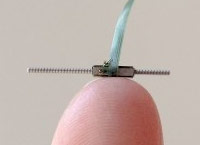

The SQUIGGLE motor is a revolutionary linear micro motor that sets new benchmarks for small size and big performance. This patented ultrasonic motor creates high force and speed with only a few parts. It replaces complex electromagnetic gearhead motors which have hundreds of parts.

This simple, robust piezo motor is scalable to much smaller sizes than electromagnetic motors, without significant loss of power efficiency. This makes it perfect for portable consumer products such as mobile phone cameras and wearable medical devices.

The SQUIGGLE Motor Operates Piezo actuators that change shape when electrically excited. A SQUIGGLE motor consists of several piezoelectric ceramic actuators attached to a threaded nut, with a mating threaded screw inside.

Applying power to the actuators creates ultrasonic vibrations, causing the nut to vibrate in an orbit - similar to a person’s hips in a “Hula Hoop.”

The rotating nut turns the threaded screw, creating a smooth in-and-out linear motion. Thread friction drives the shaft, directly converting rotary motion to linear motion.

Some of the Squiggle Motor's Features Include

No parasitic drag • less wasted power • Zero backlash (with a light pre-load) • Very high stiffness • Nanometer resolution and high force• High torque at low speeds, with no gearbox • Smooth velocity at microscopic speeds • Off-power hold • Very small diameter • Manual screw rotation for off-power positioning

The speed and position of the threaded screw can be precisely controlled. Most importantly, the screw holds its position when the power is turned off.

The SQUIGGLE motor generates no magnetic fields. It can be made from non-ferrous metals for use in MRI, scanning electron microscopy and focused ion microscopy applications.